|

| wonder sieve |

About

97 percent of the Earth's water can be found in our oceans.With ever

increasing needs of growing population, the problem

of pure,

clean drinking water

is also

growing. Providing

clean drinking water for millions of people who struggle to access

adequate clean water sources is

still a challenge. Scientists from the University of Manchester, led

by Dr Rahul Nair, show how they solved some of the challenges by

using a chemical derivative called graphene oxide. An effective and

less energy-intensive desalination process using graphene has been

developed which could give millions of people access to clean water.

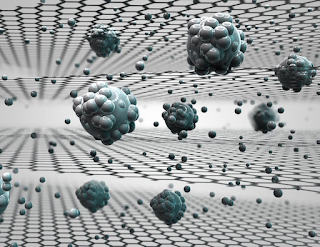

Graphene

Known

as a scientific 'wonder material', is a sheet form of carbon that is

just one atom thick. It

has

a range of startling properties including

being hundreds of times stronger than steel, extremely lightweight

and a superb conductor of electricity. Potential applications for the

man-made material have included everything from bendable smart phones

to super-capacity batteries.The

difficulty has been to produce large quantities of single-layer

graphene using existing methods, such as chemical vapour deposition

(CVD).

Currently, the production routes are quite costly.

To

make a one-atom thick graphene permeable, you need to drill small

holes in the membrane. However, if the hole size is larger than one

nanometre, the salts will pass through that hole. And the graphene

membrane needs also to be have a very uniform less-than-one-nanometre

hole size to make it useful for desalination. All in all, this is a

real technological challenge.

Existing,

industrial-scale desalination plants can be costly and normally

involve one of two methods: distillation through thermal energy, or

filtration of salt from water using polymer-based membranes. They

involve large amounts of energy, produce greenhouse gases and can be

harm marine organisms. Eventhough,

graphene-oxide

has previously been demonstrated for filtering small nanoparticles,

organic molecules and even large salts, the challenge with common

salts found in seawater is their small size.

Researchers

from University of Manchester in the U.K. have now successfully

developed graphene-oxide

membranes

and found a strategy to avoid the swelling of the membrane when

exposed to water. The pore size in the membrane can be precisely

controlled, which can sieve common salts out of salty water and make

it safe to drink, they said. They

were able

to restrict pore-swelling by coating the material with epoxy resin

composite that prevented the sieve from expanding. This means common

salt crystals could continue to be filtered out, while

leaving

behind uncontaminated, clean, drinking water.

Scalability

is one of the big factors in how viable the method is, and the

researchers believe that their graphene-oxide membrane could

comfortably scale both up and down. Upwards, and the method could

help improve the efficiency of desalination plants. Scaling down, the

filters themselves could be used as inexpensive water purifiers for

developing countries with limited access to clean water or

large-scale de.salination plants. The

sieve uses a graphene oxide membrane to filter out the common

salt,

with holes in the sieve less than one nanometre in size (0.000001mm).

When

the common salts are dissolved in water, they always form a ‘shell’

of water molecules around the salt molecules. This allows the tiny

capillaries of the graphene-oxide membranes to block the salt from

flowing along with the water. Water molecules are able to pass

through the membrane barrier and flow anomalously fast which is ideal

for application of these membranes for desalination plants where vast

volumes of water may flow through on a daily basis.

It

is found that permeation

rates for the membranes decrease exponentially with decreasing sieve

size, they also report that water transport itself is only “weakly

affected” meaning the filtered water flows through the membrane

relatively quickly; an important factor if the aim is to develop

affordable desalination technology.

It

is hoped that graphene-oxide membrane systems can be built on smaller

scales making this technology accessible to countries which do not

have the financial infrastructure to fund large plants without

compromising the yield of fresh water produced.

At

this stage, the technique is still limited to the lab, but it's a

demonstration of how we could one day quickly and easily turn one of

our most abundant resources, seawater, into one of our most scarce -

clean drinking water. these

graphene-based sieves could change lives around the world. But before

that happens, the team has to make sure they can withstand prolonged

contact with seawater. They also need to test the material against

current membranes desalination processes use. would be an enormous

breakthrough in worldwide water supply.

No comments:

Post a Comment